Turnkey installations

Thanks to the synergies generated by the Arcade group, we have established ourselves as one of the preferred suppliers of turnkey water treatment installations for:

- The production of ultrapure water (UPW)

- Waste water treatment (WWT)

- The reclaiming or recycling of process water streams

Industrial production processes are becoming more and more specific and complex. To keep your installations up to date we offer our customers precisely matched water treatment and process plants with state-of-the-art technology. You will receive a comprehensive individual consulting from our competent experts. As part of the execution, we support you from planning (plant analysis, basic and detail engineering, design) to assembly and commissioning over the entire project or provide assistance for specific parts of your project.

Plant audit

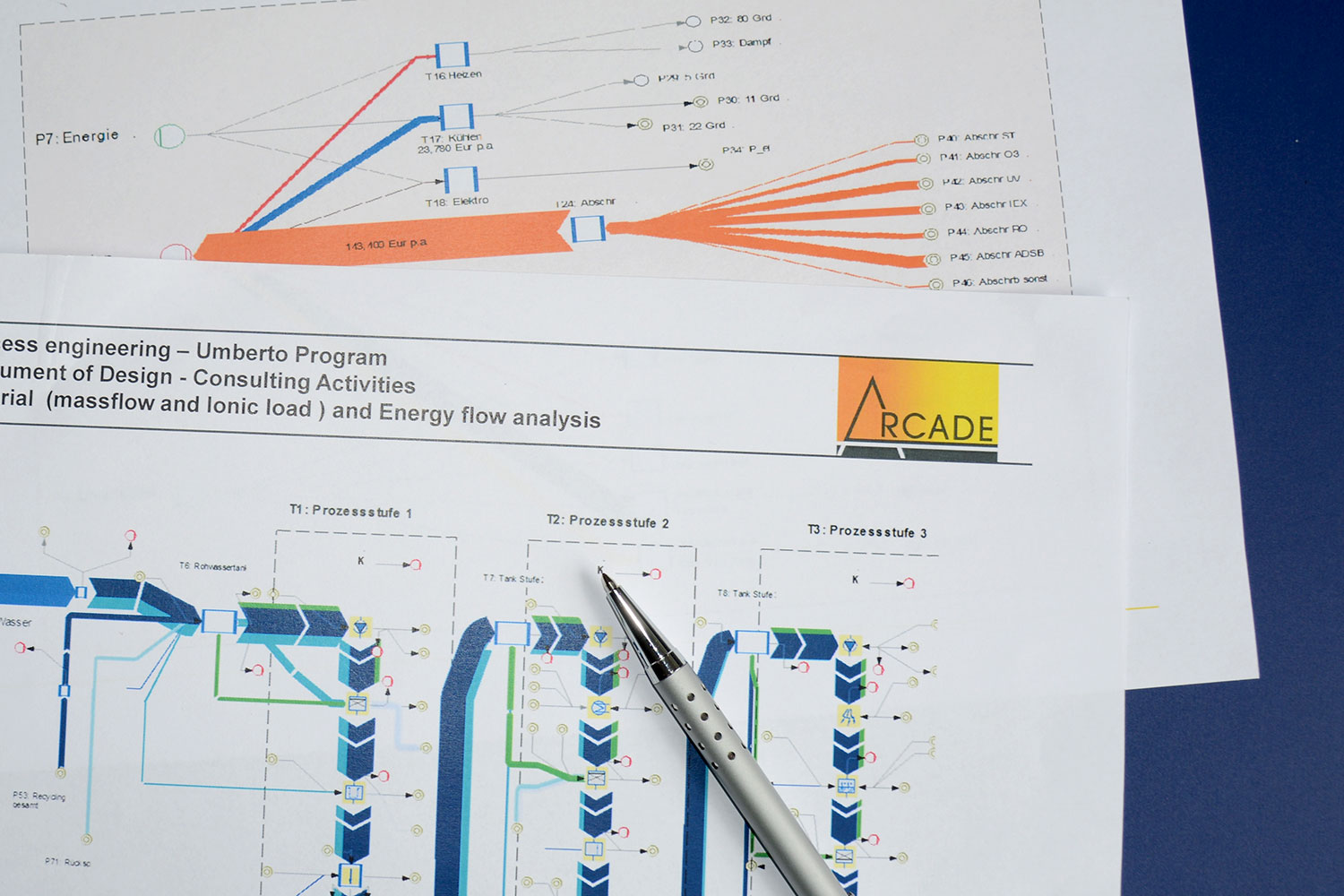

A major focus of our plant planning are optimisation concepts to meet steadily increasing quality requirements for products and process streams. By creating mass, energy and material flow balances, we evaluate the performance of existent plants and identify possible expansion potentials. These analyses reveal existing capacity gaps, which are presented by way of a series of balance graphs.

Through the visualisation, water flows, service flows, capacity reserves and gaps can be identified in different colours. The energy balances are calculated simultaneously with the mass balances. The hierarchical model can be flexibly expanded, and individual components can be viewed separately.

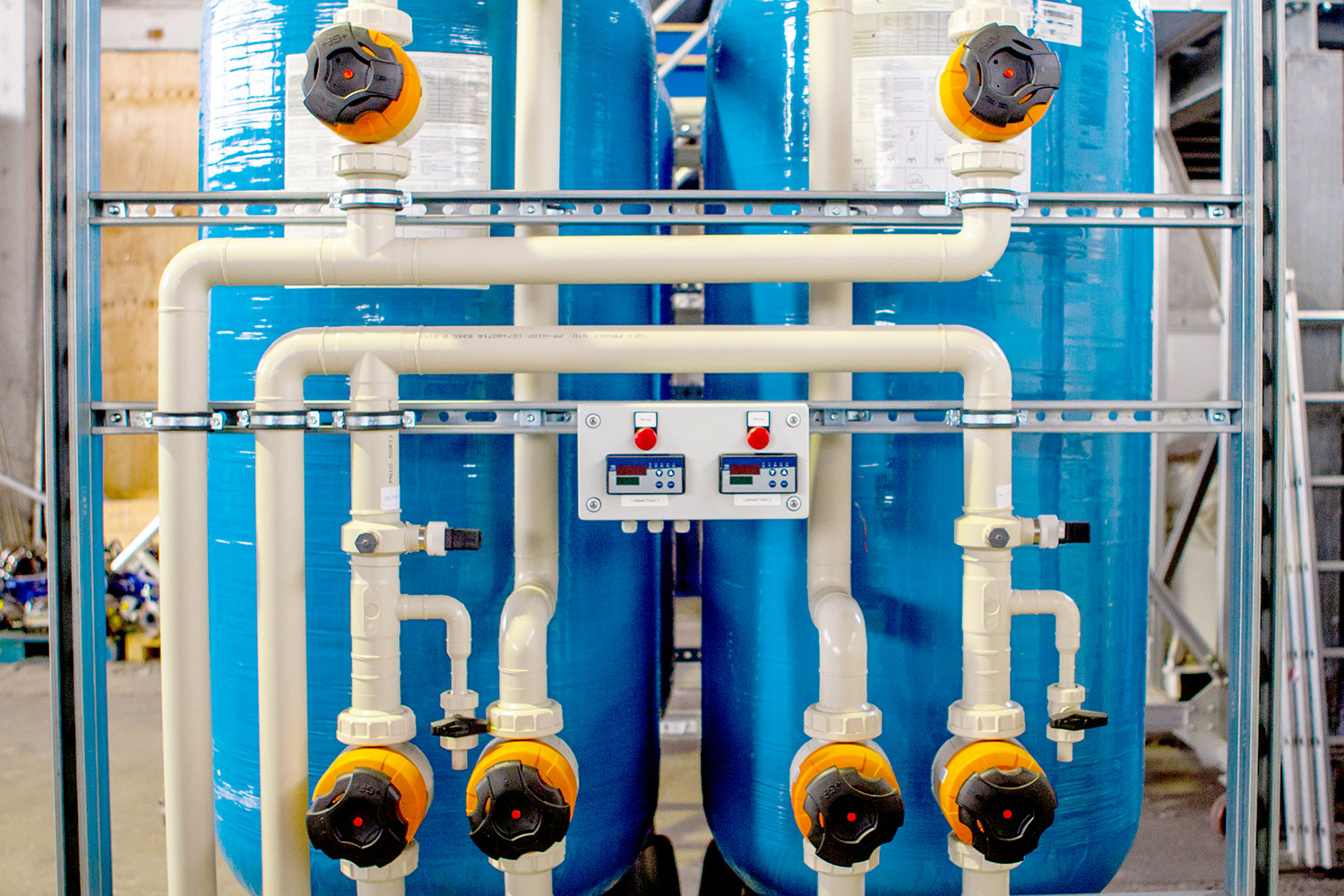

Basic and detail engineering

Basic engineering design:

- We design the process flow and basic reaction

- We plan state-of-the-art installations integrating the latest developments in terms of efficiency and energy economy

Detail engineering design:

- We select appropriate components and materials for your process

- We size the installation based on the requested capacity, the selected process and constraints imposed by other systems and components

- We calculate the operating media volumes, running time and the regeneration cycle for the following processes:

– ion exchange

– activated carbon

– multimedia filters

– membrane filters

– reverse osmosis

– nano-filtration

We verify the thermal and thermodynamical balances and define the necessary monitoring and control instruments.

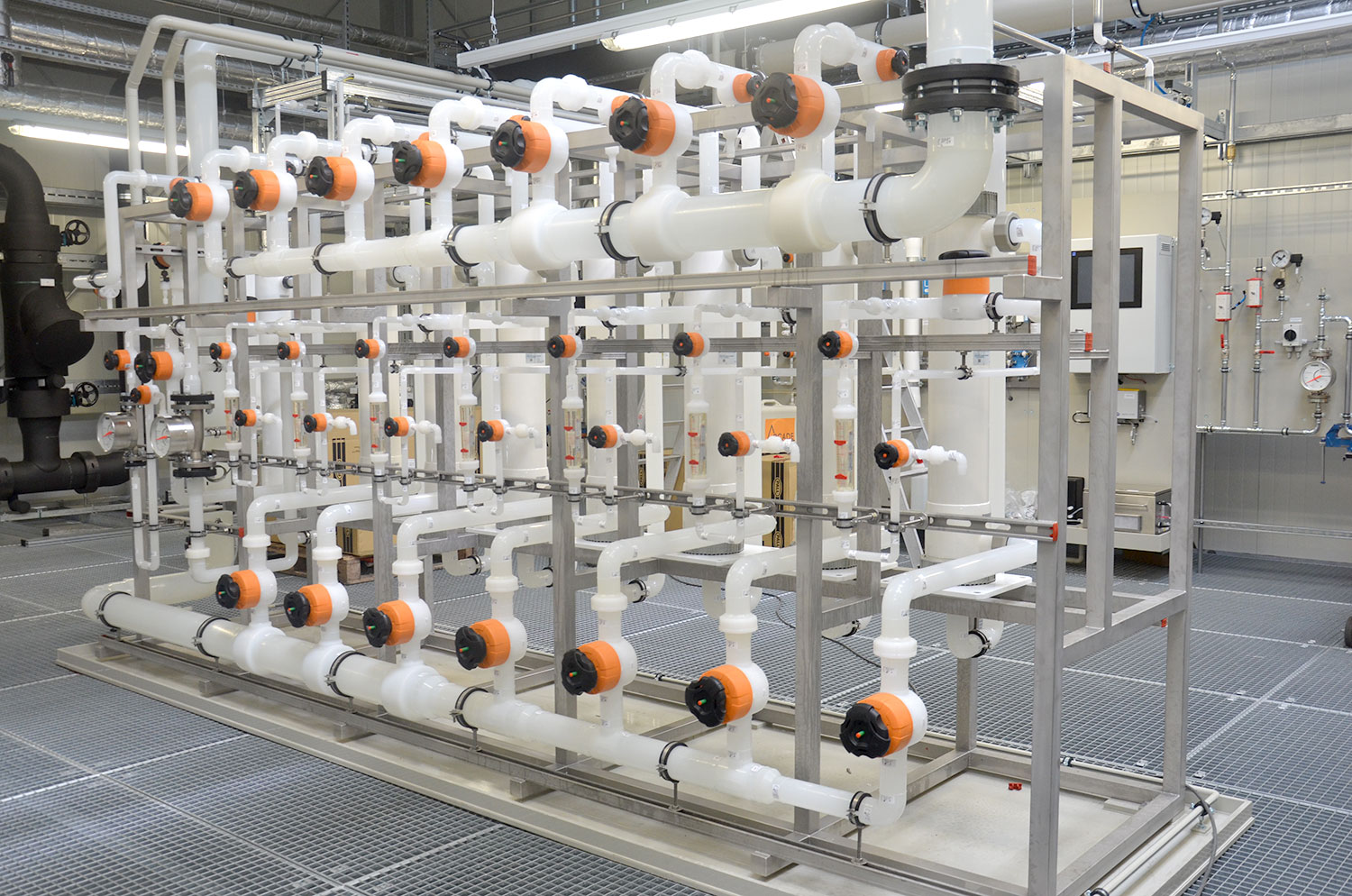

Montage

We offer you the commissioning of the delivered equipment as per the contractually defined condition, as well as the turnkey handover.

The assembly of components or skids is mainly carried out in our workshop. We supply the prefabrication, installation and set-up of all mechanical and electrical components.

We exclusively use our own staff for construction management and supervision during the installation of the plants.

Commissioning

In addition to the planning and installation or optimisation of an installation, we also offer the commissioning of the process and of the mechanical and electrical design.

We take in charge the verification, optimisation and validation of the installations during the commissioning phase in compliance with the contract specifications regarding:

- Security and functions;

- Availability and sustainability;

- The defined performance parameters.

Proof of quality is provided by the accompanying documentation and certification. On request we offer training services for your personnel.

Analytics

For industrial water treatment, continuous monitoring of quality parameters is indispensable. Besides ensuring the consistent processing capacity of the individual process steps, the control of water quality at the point of use is a crucial task. For comprehensive process monitoring, we work with an optimal combination of online measurements and laboratory analyses. The selection of devices is made irrespective of the manufacturer and depends on the jointly defined monitoring requirements.

We offer the implementation of plant-accompanying sampling and analyses by our own qualified personnel as well as the involvement of certified analytical laboratories.

You have a project? Contact us!